MAGNETIC BULLETS SEPARATOR, Bullet magnetic separators

Magnestic FILTRATION

Get In Touch

BULLET MAGNETIC SEPARATOR,BULLET MAGNETS:

suitable for use with dry and semi-dry powders, granulates, and lumps.

Magnetic bullet separators, also known as bullet magnets, are a powerful and efficient way to remove ferrous metal contamination from dry, granular or powdered products. They are used in a variety of industries, including food, pharmaceuticals, and chemicals, to ensure product purity and quality. If you’re looking for a reliable and effective way to remove metal contaminants from your products, magnetic bullet separators are an excellent choice.

At Sinoneo Magnets, we offer a range of magnetic bullet separators to suit your specific application needs. We can provide custom sizes, shapes, and magnetic strengths to ensure that you get the perfect separator for your specific requirements. Our team of experts can help you choose the right separator for your application and provide advice on the best way to use and care for your separators.

The Benifits of

bullet magnetic separator

1. High magnetic strength.

Bullet magnets are housed in stainless steel and feature a high-intensity magnetic bullet element mounted centrally.They are able to attract and hold even the smallest ferrous metal particles, ensuring that your products are free from contamination. They can remove anything from fine metallic dust to larger pieces of metal, making them a versatile solution for a range of applications.

2. Easy installation and maintenance.

They are designed to fit into existing pipelines, so they can be installed with minimal disruption to your production process. They are also easy to clean and maintain, with no moving parts or complicated mechanisms that can break down or cause problems.

3. Incredibly durable and long-lasting.

They are made from high-quality stainless steel and have a strong magnetic force, which means they can effectively capture and hold ferrous particles over a long period of time. They are also designed to be easy to clean, ensuring that they remain effective and efficient over the lifetime of your production line.

4. Maintains Full Flow.

The design of bullet magnets ensures that the product flow is not hindered by the magnetic element. This allows for uninterrupted material processing.

These benefits make bullet magnets are a reliable and efficient solution for ensuring product purity and equipment protection in various industrial applications.

5. Quick Cleaning.

Cleaning the magnetic cone is a breeze with our easy-clean design. The cone is fixed to the door, and when you open the door, the magnetic cone is released simultaneously. To clean the cone, simply wipe it down with a glove or cloth. This ensures that your magnetic system stays in top working condition and maintains its effectiveness.

Why us

REASON TO CHOOSE SINONEO MAGNETIC BULLET SEPARATORS

Quality Guarantee

You’re going to love our services! We guarantee 100% quality and the best customer experience. You’ll receive exactly what you’re looking for!

OEM SERVICES

We’re happy to accept OEM and small orders, and we’re always willing to provide prototypes upon request for you.

Availble Custom Design

We offer magnetic bullet filters that can be customized to meet your unique needs for any operation!

Quick Delivery

We can deliver customized bullet magnet separators within weeks, not months. This will save you both time and money!

Get a free Custom Quote for your BUSINESS now!

Our friendly magnet engineers are here to help you get exactly what you need for retail or industrial purposes, with super high quality & a competitive price.

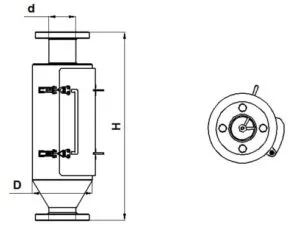

THE SPECIFICATION OF

our magnetic bullet magnets

| Model No. | Size(mm) | ||

| d | D | H | |

| SMBM50 | 51 | 114 | 380 |

| SMBM65 | 76 | 168 | 540 |

| SMBM100 | 108 | 219 | 586 |

| SMBM150 | 159 | 273 | 655 |

| SMBM200 | 219 | 325 | 760 |

| SMBM250 | 273 | 426 | 850 |

| SMBM300 | 325 | 480 | 880 |

All dimensions are in millimeters, and if you need any additional dimensions, just let us know! We’re happy to help!

HAVEN’T FIND WHAT ARE YOU LOOKING FOR?

We can personalize every aspect to perfectly match what you’re looking for – from the materials and size to the shape, temperature, surface treatment, and installation method.

THE OPTIONS OF

Sinoneo magnetic bullet filters

Here are some of the optional features that you can select when choosing magnetic bullets:

1. Housing Material:

Frames and housing materials are available in SS304, SS316, and SS316L, ensuring a high level of durability and resistance to wear and tear.

2. Surface Finishing:

Fine polishing, dull polish, or sandblasting, provide a sleek and professional appearance that can match your specific application needs.

3.Magnetic Strength:

A wide range of magnetic force options, including 2000Gs, 4000Gs, 6000Gs, 8000Gs, 10000Gs, and 12000Gs, allows you to choose the strength of magnet that best suits your requirements.

4. Operation Temperatures:

Maximum working temperatures range from less than or equal to 80, 100, 120, 150, 180, and 200 degrees Celsius, ensuring optimal performance in your application.

5.Installation type:

Different installation types are available, including flange, quick-release clamp, or pipe, giving you the flexibility to choose the installation method that works best for your specific application.

We offer customization options for customers who have specific designs or specifications in mind. Our team is committed to working with you to create a magnetic bullet that meets your unique needs.

In addition to our high-quality magnetic bullet separators, we also offer competitive pricing and fast turnaround times. We understand that every application is unique, which is why we work closely with our clients to ensure that they get the best possible solution for their specific needs.

So if you’re looking for a reliable and efficient solution for removing ferrous contaminants from your dry and free-flowing products, look no further than magnetic bullet separators from Sinoneo Magnets. Contact us today to learn more about how we can help you protect your product and equipment with the very best magnetic separation solutions on the market.

Faq

Read The FAQ’s

How do bullet magnets work?

Our Magnetic Bullet is equipped with a powerful magnet that effortlessly attracts impurities. The convenient cleaning door makes removing iron easy, ensuring optimal machinery performance.

What types of magnetic materials are used in the construction of magnetic bullets?

The Bullet Magnet consists of a bullet-shaped magnetic core and a stainless steel housing. The core is usually made of permanent magnets, like neodymium (NdFeB) or SmCo magnets, which have strong magnetic properties and are highly effective at capturing and retaining magnetic particles.

Can magnetic bullets be customized to fit specific equipment or processing needs?

Our products can be customized to fit your specific equipment or processing requirements. We offer different sizes, shapes, and configurations to ensure seamless integration into your existing systems.

Are there any safety precautions or guidelines to follow when handling or maintaining these devices?

When working with magnetic bullets, it’s really important to follow safety guidelines to avoid injuries caused by the strong magnetic fields. You should always wear suitable personal protective equipment and make sure to avoid direct contact between magnetic bullets and sensitive electronic devices or credit cards.